A sculptural wireless

speaker concept.

A sculptural wireless speaker concept blending the minimal, sensorial world of Tamburins with Bang & Olufsen’s audio legacy. Designed and built from scratch as a working prototype under the brief of designing and building a fully functional speaker., this project explores material storytelling and form-driven acoustics.

Tamburins x Bang & Olufsen

Speaker

2024

———————————————————

14 WEEKS

———————————————————

BRAND RESEARCH

CONCEPT DEVELOPMENT

PROTOTYPING & FORM EXPLORATION

ENGINEERING

YEAR

———————————————————————--——

DURATION

—————————————————————--————

SKILLS

What if Tamburins’ artistic identity met Bang & Olufsen’s engineering precision?

THE GOAL

To concept, design, and build a fully functioning speaker from scratch—considering both visual brand alignment and sound performance.

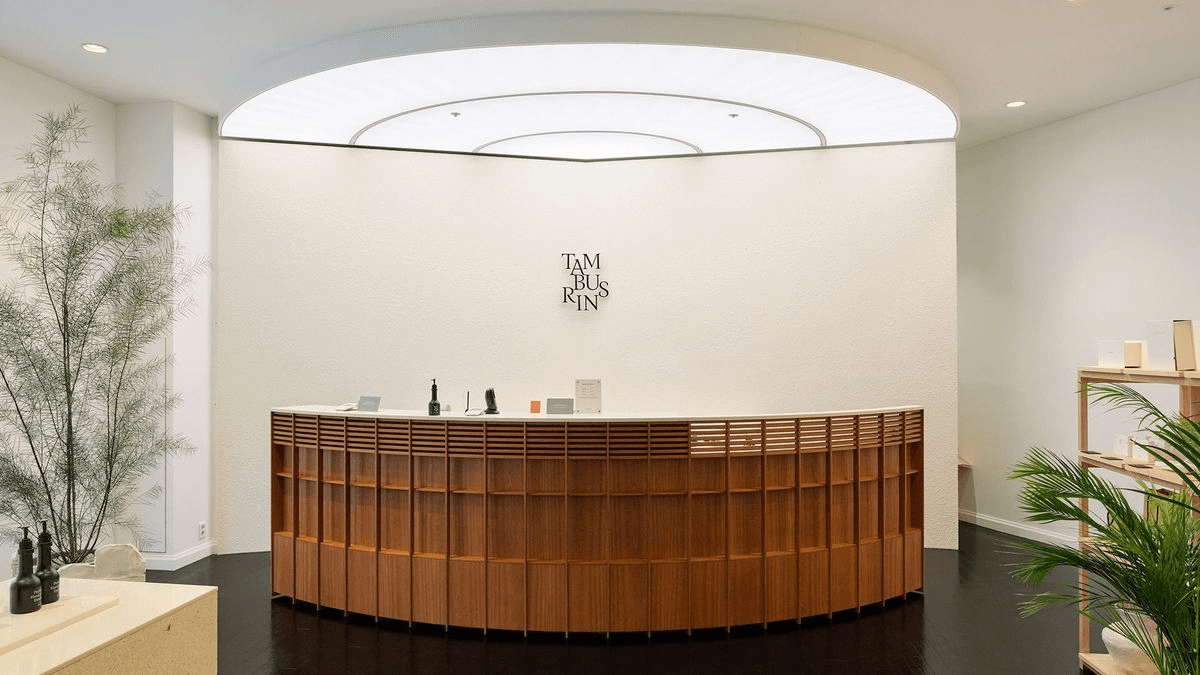

Merging Tamburins and Bang & Olufsen creates a brand expression where sculptural artistry meets engineered clarity. Tamburins contributes its poetic, sensory-driven identity, while B&O brings precision acoustics and minimalist refinement.

Rooted in Tamburins’ iconic egg silhouette

- soft, sculptural, and instantly recognizable.

Achieving equilibrium between

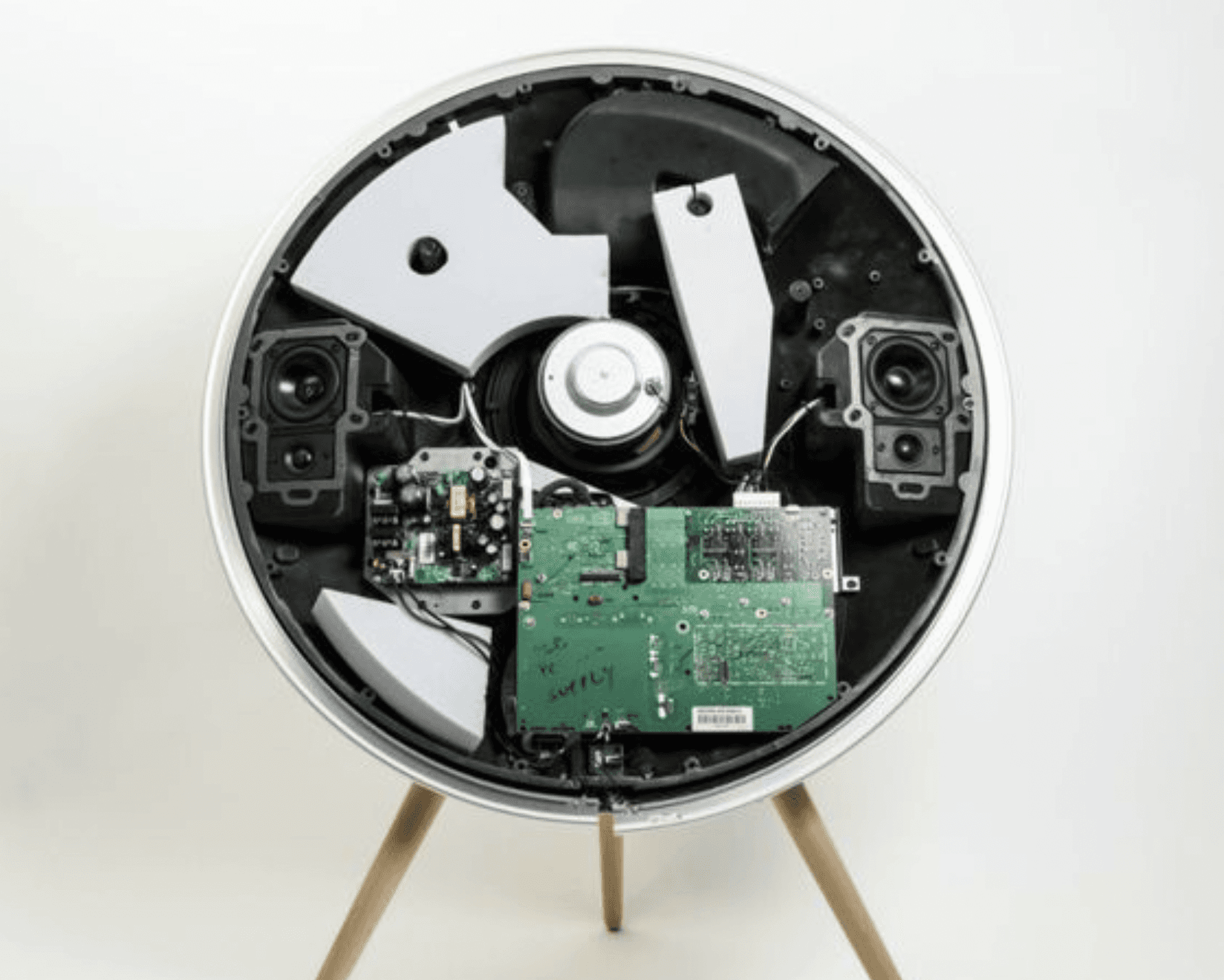

The design explores the contrast that defines this collaboration: Tamburins’ smooth, organic form language paired with Bang & Olufsen’s highly technical audio architecture. A transparent shell would allow both qualities to coexist without compromise—the softness of the exterior contour frames the intricate machinery within, revealing the craft, structure, and acoustic clarity that B&O is known for.

Envisioned Space

A speaker where poetic form meets industrial honesty

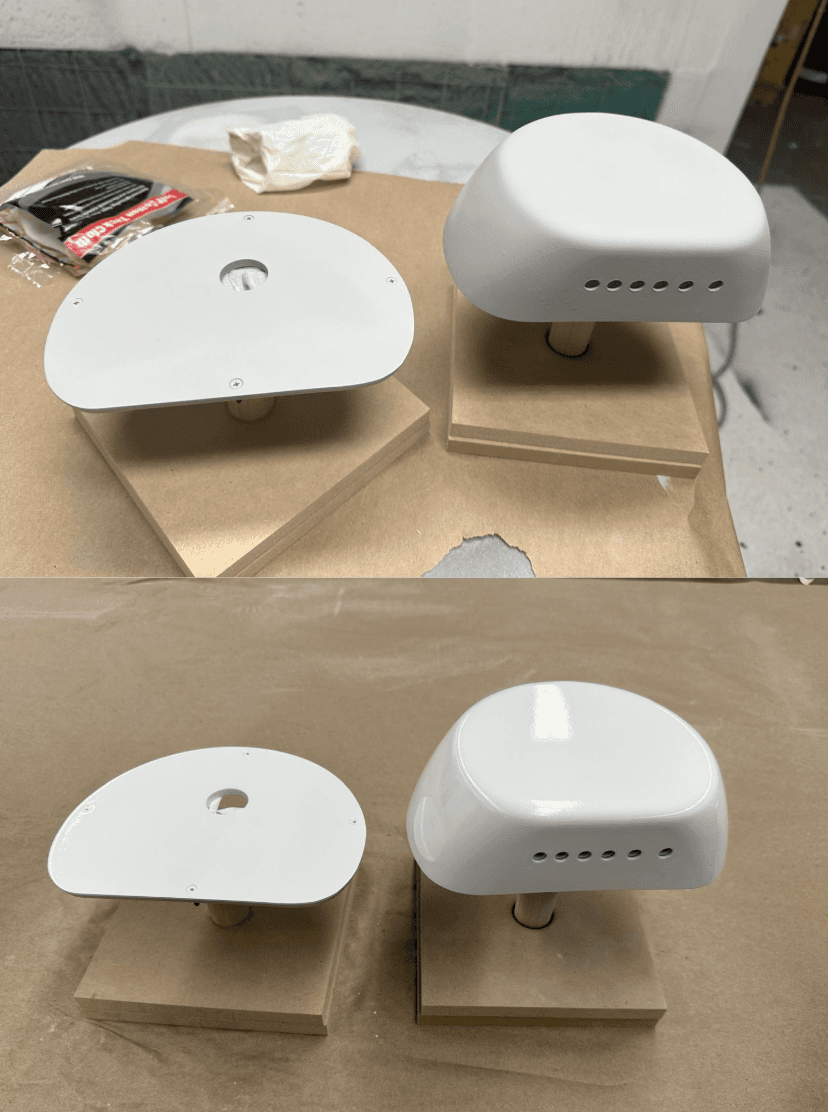

Learning Prototype

Sony SRS-XB23 Teardown

To understand how compact Bluetooth speakers manage internal architecture, component layout, and acoustic pathways, I began with a full teardown study of the SONY SRS-XB23. This teardown served as my Prototype 0 phase—an early exploratory model used purely for learning, not for final form development.

Concept and Form Development

Throughout the project, rapid prototyping was essential for quickly testing form, proportions, and internal component fit.

Final Prototype Process

An overview of the fabrication steps, component integration, and final assembly process.

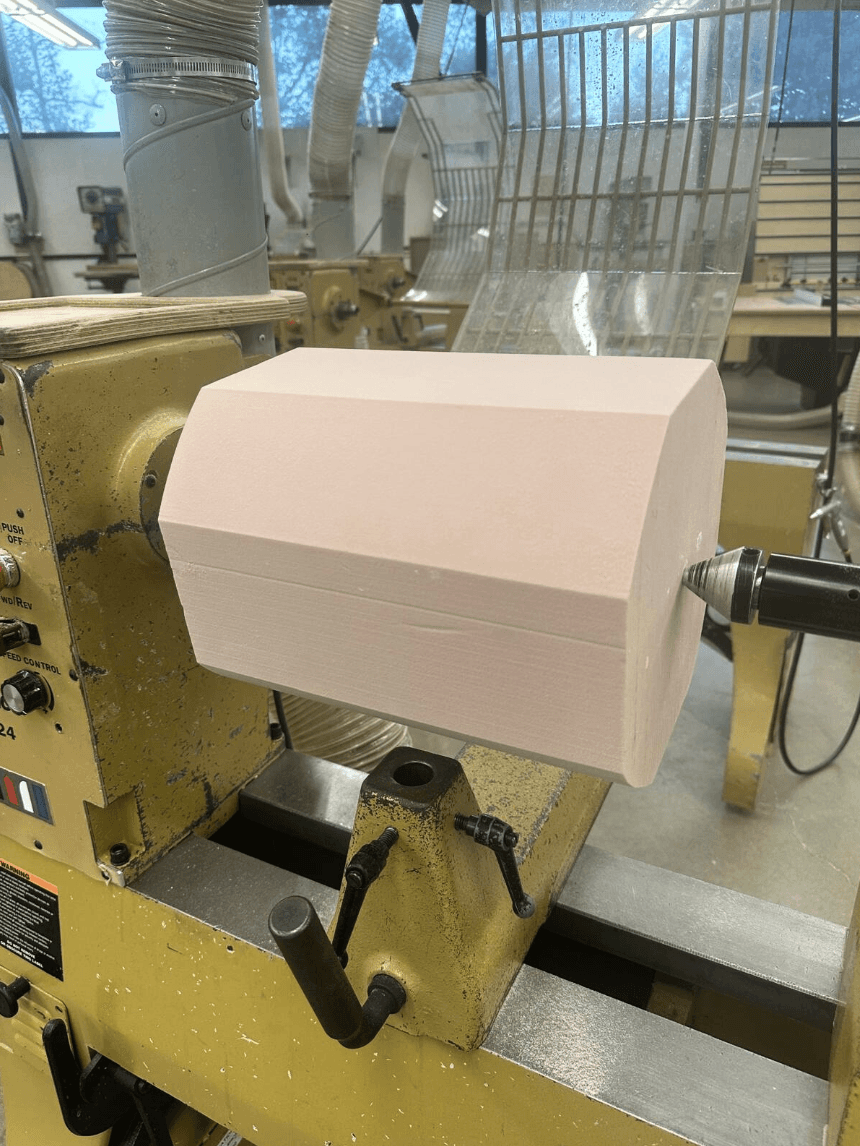

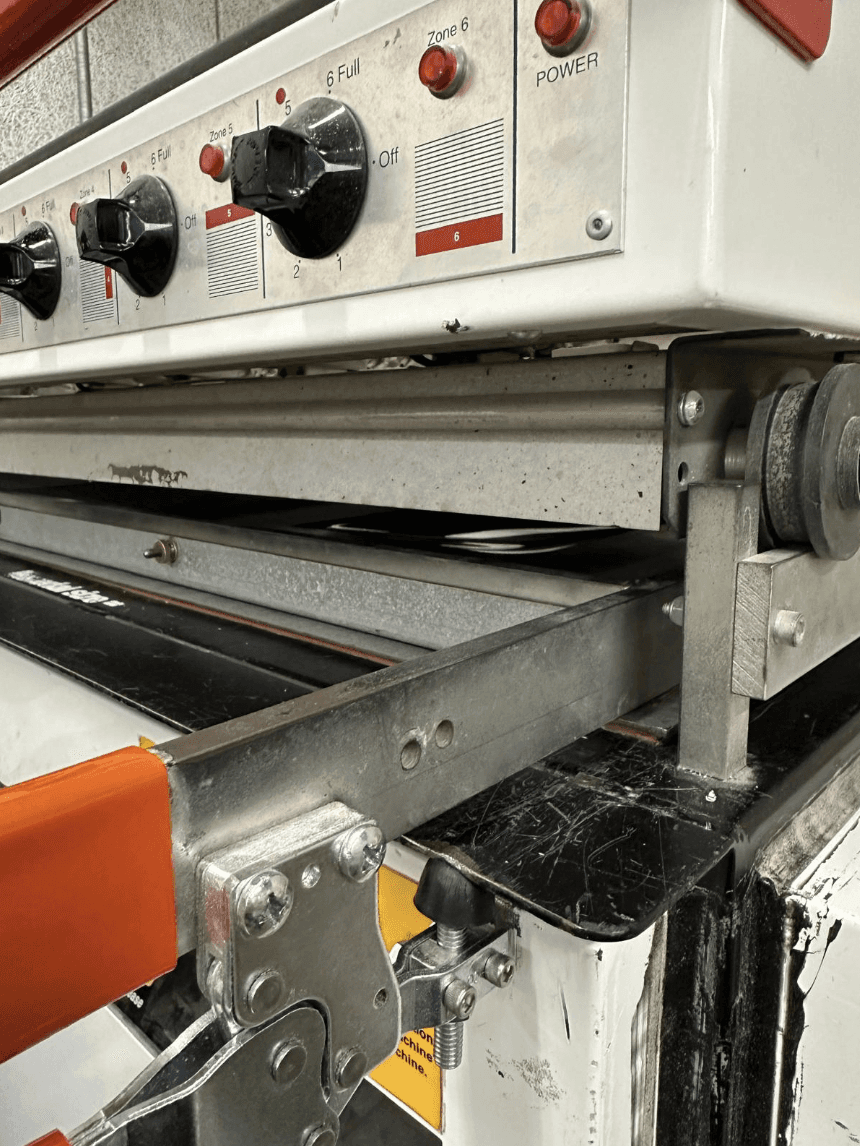

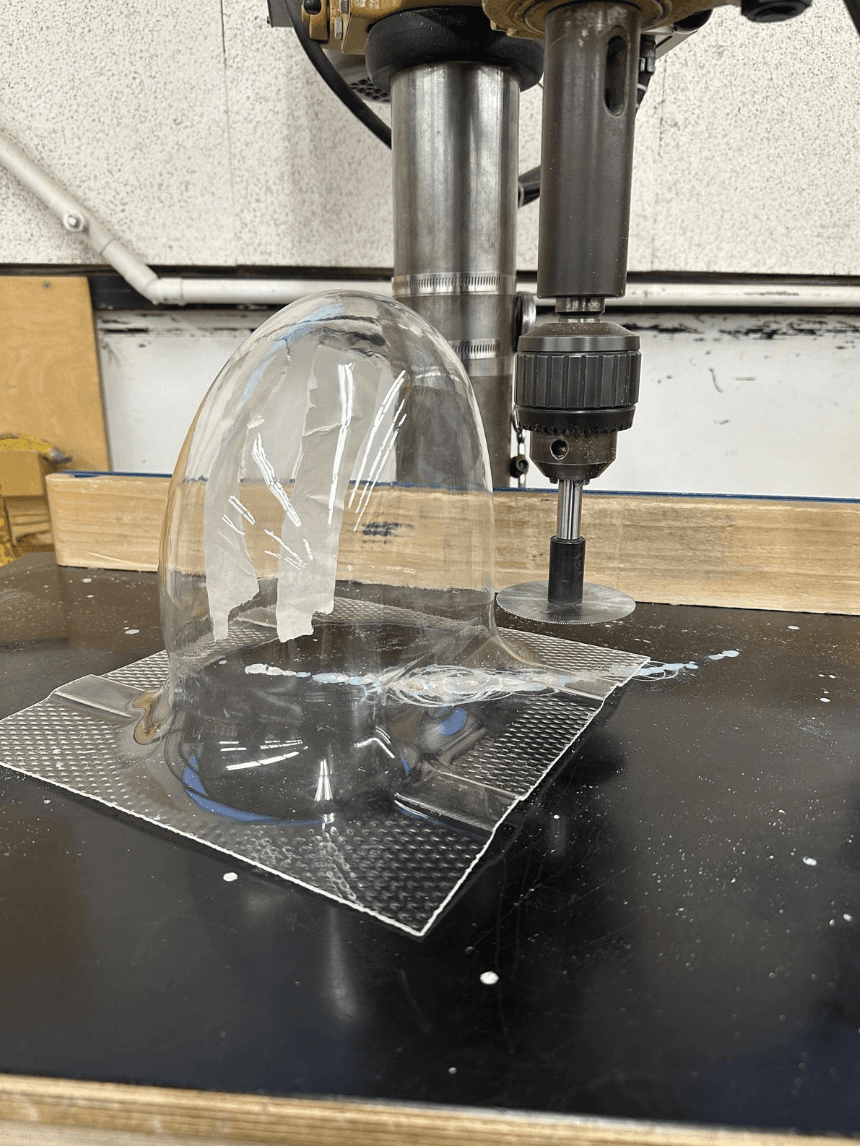

Dome Fabrication

To create the dome, I first turned the form on the lathe using foam. After shaping it accurately, I spent several days and multiple attempts vacuum-forming acrylic over the dome to achieve a smooth, consistent shell.

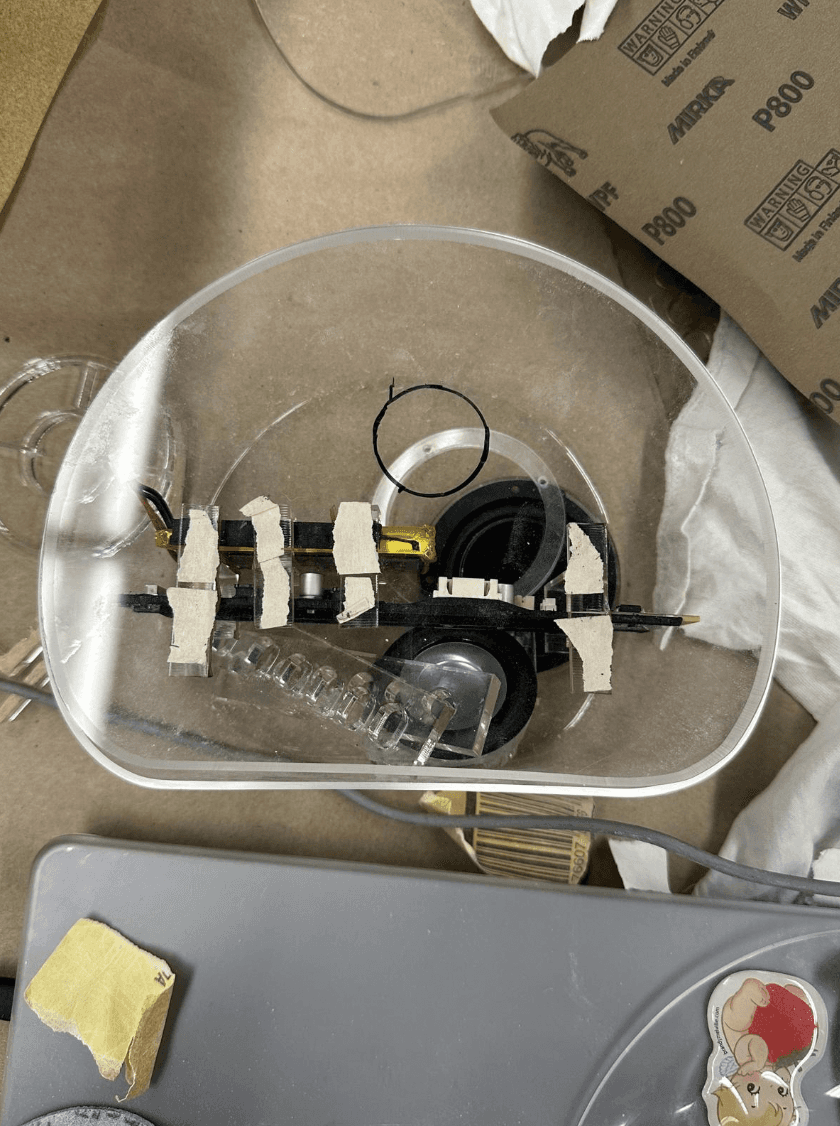

Finishing & Assembly

The final stage involved surface finishing—sanding, priming, and painting—followed by internal integration. I soldered and managed the wiring, and established the component layout for the PCB, spring board, batteries, and button mechanisms.